Quality Check

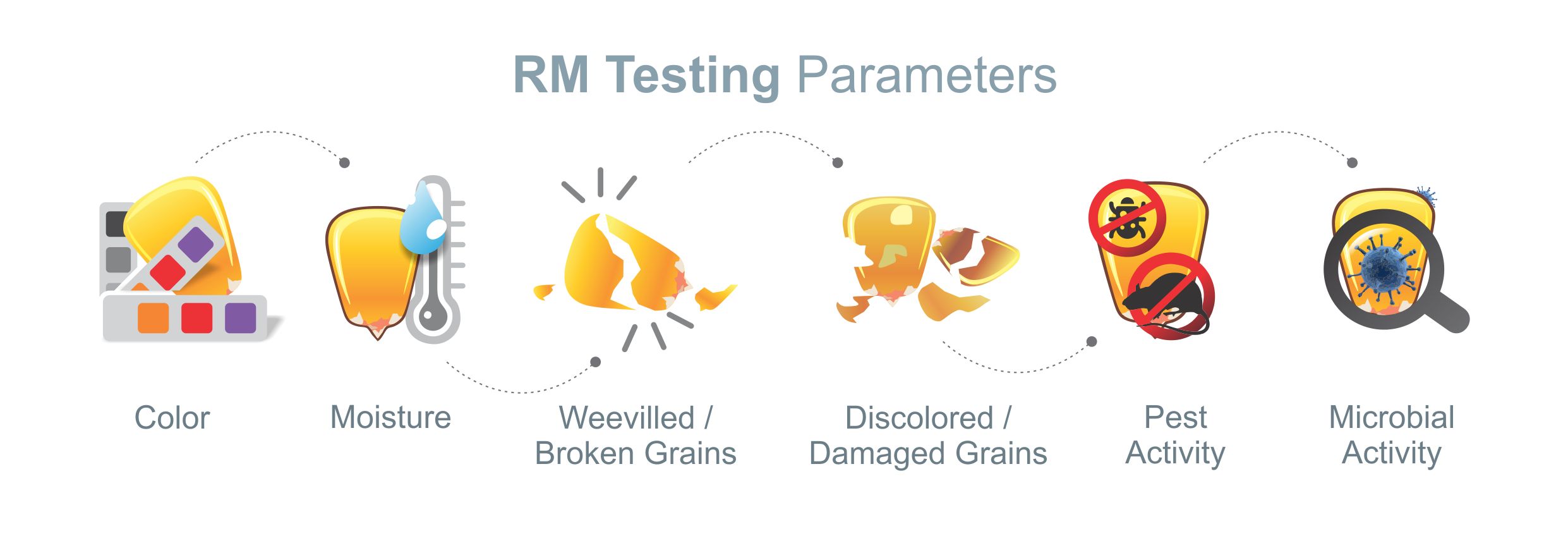

Raw Material Testing

Company is procurring all the raw material from approved suppliers. A policy of approving the suppliers is there in system as per ISO 22000:2005.

All the raw material is checked at the time of receiving by unloading supervisor @ quality offiers.

Color - Moisture - Weevilled / Broken grains - Discolored / Damaged grains - Pest activity - Microbial activity

Frequency

Every vehicle is tested & records maintained.

Production Activities

Godawari Udyog, India manufactures their products accrding to Good Manufacturing Practice(GMP). The hygiene standards applicable to the production of Maize Grits as regulated by local and Indian regulations are carefully observed. The processes are regularly audited by our Quality Management Department.

Food Grade

All products are manufactured according to GMP, are fit for human consumption when applied to food and comply relevant legislation covering the product.

Pest Control Management

Company has hired pest control agency for pest control

Treated Water

During processing company uses treated potable water.

Production activities are carried out in controlled manner complying with the safe environment.

Final Product Testing

Raw material as well as finished goods analysis is carried as per laboratory manual by the quality control department. The inprocess checks are carried out and records are maintained.

Finished Goods Testing Parameters

Moisture | Microbial testing | Particle size distribution | Uric Acid | Total ash | Pesticides | Protein

Heavy Metals | Fat content | Acid insoluble ash | Alcoholic acidity | Crude Fibre | Aflatoxin (Kit)

Post Process Conditions

The Finished product is finally packed in Polywoven bag with HMHDPE liner for 50kg packing & FIBC for 1 Ton packing in hygenic environment under strict supervision.

Counter samples of finished products are kept for analysis in in-house laboratory on regular basis.

Dispatch is done after vehicle inspection & in good hygenic condition. COA is sent along with vehicle.